Intelligent PHA Methodology: Through the Eyes of the Facilitator

October 31, 2020

Following the creation of OSHA’s Process Safety Management (PSM) Standard 29 CFR 1910.119, the process industries continue working to improve Process Hazard Analysis (PHA) processes. Early efforts to improve PHA processes were scattered in the way studies were conducted, teams were made up, and results were corrected. These problems came to light when the first round of PSM Compliance Audits were conducted and a number of quality issues in those studies surfaced. Some of these findings included:

- Single inconsistencies such as: severity differences for identical hazards, failure to make recommendations for unacceptable risks, irrelevant recommendations (e.g., general safety), missing hazard scenarios or skipped equipment checks, untrained facilitators

- Organization-wide inconsistencies, including identical / similar processes with significantly different findings – still a common challenge for many companies

- Companies using What-If or Checklist PHA methodologies to tackle complex processes

- Recording by exception (e.g., only incidents deemed important are documented)

- Failure to follow standard protocols or generally accepted guidelines

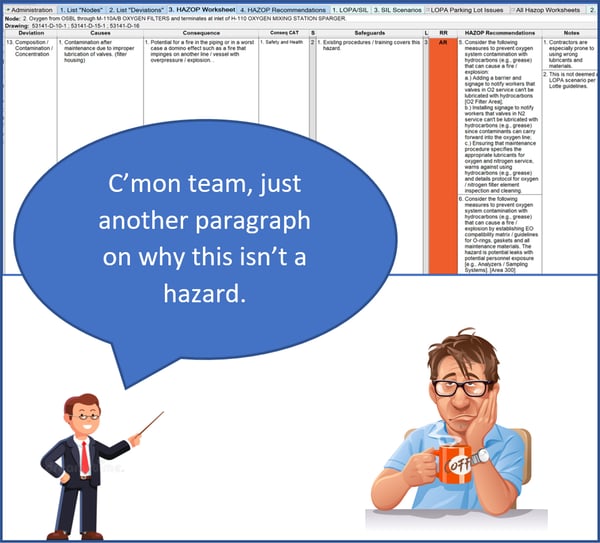

While the process industries have made considerable progress in improving the conduct and quality of PHAs, new challenges have materialized while many of the original ones are still in play. We’ve moved away from poor recording habits to writing PHA novels focused on documentation instead of hazard identification. Why is this happening? Why are hazards being missed in PHAs meant to catch them?

The primary reason is the impact of fully recording the PHA study to meet regulatory requirements. This exercise is routine and easily identified, so the effort to document all the causes for deviation requires substantial effort for minimal return. When a significant portion of any PHA consists of regulatory accounting, the team becomes disengaged – not the best mindset for hazard identification. Organizations must find a balance between meeting industry requirements and draining the energy of the team in charge of conducting PHAs.

Solution

PHA facilitators are a finite resource – no matter how experienced and adept they may be – and these studies are heavily reliant on a single person for quality assurance; the facilitator must be, in a sense, the Swiss Army knife of the team. Their responsibilities often supersede simple facilitation and other PHAs encroach on the work needing to be done for each individual PHA study. Frankly speaking, PHA facilitators are stretched thin across multiple PHA studies and have multiple responsibilities for each one. How do we solve that problem?

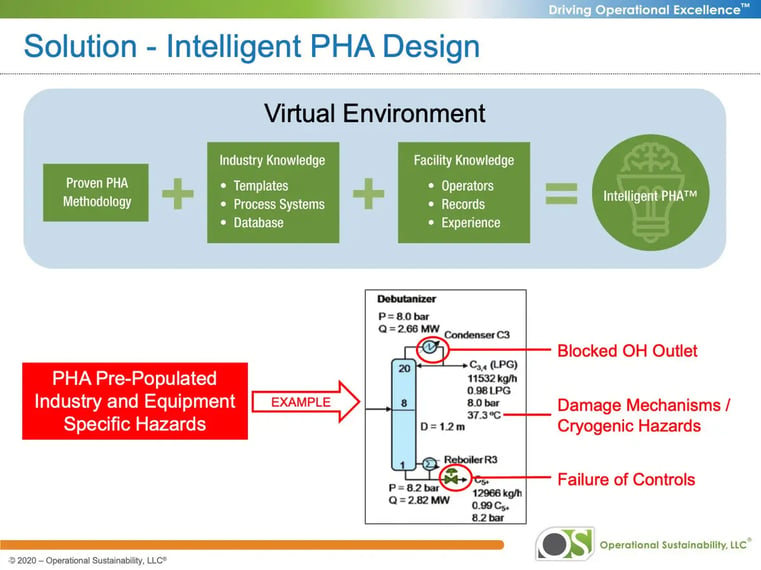

An Intelligent PHATM framework supports facilitators and improves processes. This framework includes:

- Developing PHA Procedures based on industry best practices

- Documented noding philosophy

- List of required deviations with definitions and usage

- Sound Risk Ranking Methodology

- Quantification of determining the extent of Hazard Scenarios

- Documentation guidelines for Non-Hazard Scenarios

- Explanation of Human Factors and Facility Siting Checklists

- Corporate-Wide Internal Incidents / External Industry Incident Learnings

- Facilitator / Team Training & Qualifications

- PHA internal and external learnings by industry and equipment type

- Leveraging software for more than study documentation

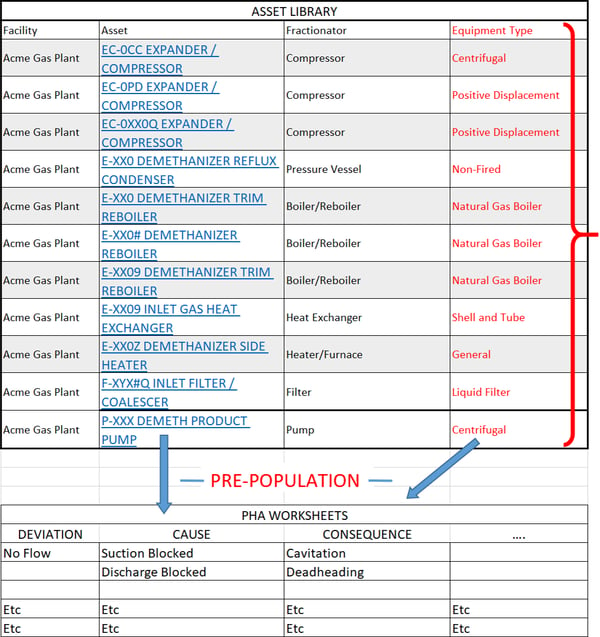

Intelligent PHA supports the facilitator by providing a knowledge database, which serves as a sound foundation that contains industry equipment templates, information based on consensus codes / standards, and other industry best practices. It is equipment-based, so any specific piece of equipment will provide PHA Cause-Consequence pairs for review by the PHA Team. If a facilitator knows the right questions to ask, they will have a pre-populated list of standard scenarios during preparation.

This process helps prevent missing standard hazard scenarios, because the process of selecting equipment is more efficient. Teams can validate or adjust scenarios as necessary, rather than spending big chunks of time identifying causes. Ultimately, the team has more time to focus on identifying major, potentially subtle hazards. While the Intelligent PHA process and tools do not absolve the team of their hazard identification responsibility, they do help the team better do accomplish their tasks.

Summary

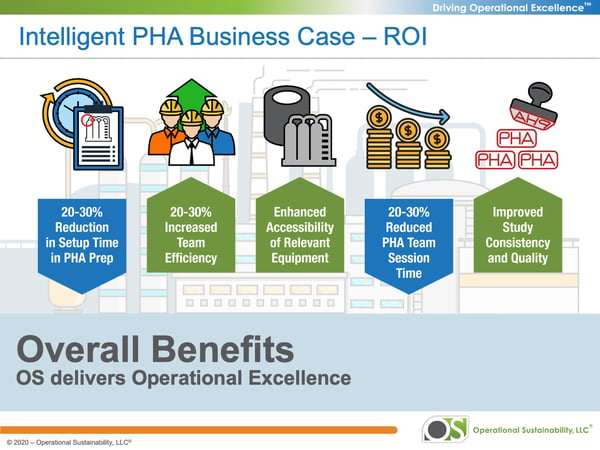

The Intelligent PHA database offers the following benefits:

- Greater assurance of PHA quality

- Increased team engagement and session efficiency

- Decreases time required for facilitator pre-work

- Provides a baseline hazard identification effectiveness margin

- Drives consistent PHAs across an organization

- Enables quality assurance via software controls

- Maintains study database for Management of Change (MOC) / incident investigation use

- Seamlessly integrates with OESuiteTM modules

The Intelligent PHA database is your key to improving the quality of PHAs across your organization, while simultaneously reducing risks and ensuring compliance with industry regulations. The Operational Sustainability, LLC® Intelligent PHA database helps you meet regulatory requirements and ensure hazards are identified quickly and accurately.

Is your organization ready to explore a more effective PHA process? Schedule a consultation.

Topics of Interest

- Asset Strategy / Asset Performance Management (9)

- Compliance Management (5)

- Conduct of Operations (11)

- Cultural Safety (4)

- EHS / Sustainability (3)

- Enterprise Loss Prevention (8)

- Management of Change (8)

- Mechanical Integrity (3)

- Mobile Applications (5)

- Operational Excellence (11)

- Operational Readiness (7)

- Operational Risk Management (15)

- Organizational Performance (7)

- Press Releases (7)

- Process Safety / RMP (23)

- Production / Value (3)

- Workforce Competency / Connected Workforce (11)