Enterprise Loss Prevention and the Interface to Operations

October 28, 2021

In challenging economic times, many companies focus on optimizing existing production facilities instead of expanding or investing in new ones. The ‘hidden factory’ is an often-unexplored source of additional capacity that can be tapped without the need to invest heavily in production upgrades.

To unlock the capacity of the hidden factory, production numbers need to be reported accurately and losses need to be tracked, categorized, and systematically reduced.

Many companies use spreadsheets to track production losses and determine whether they made their production targets on a monthly or quarterly basis. This is a retrospective process and does not provide the required information to define effective actions to improve production. A more accurate process is required to identify, categorize, and prioritize losses and reconcile them to prevent future losses.

In addition to preventing future losses due to production issues, a wide variety of risks impose another threat to future production numbers. Reliability, integrity, and safety risks jeopardize production planning and personnel safety in and around the plant. Some of these risks are captured in separate systems, mostly starting with safety risks as they are driven by compliance. Often there is no integrated view on how these risks may impact future production and cause additional unwanted losses, downtime, and human accidents. Why is an integrated view often a challenge?

The EHS department tends to live in a separate silo that focuses on slips & trips, spills, and near-misses – typically logging unwanted events in an EHS incident reporting software solution that often exists in a vacuum.

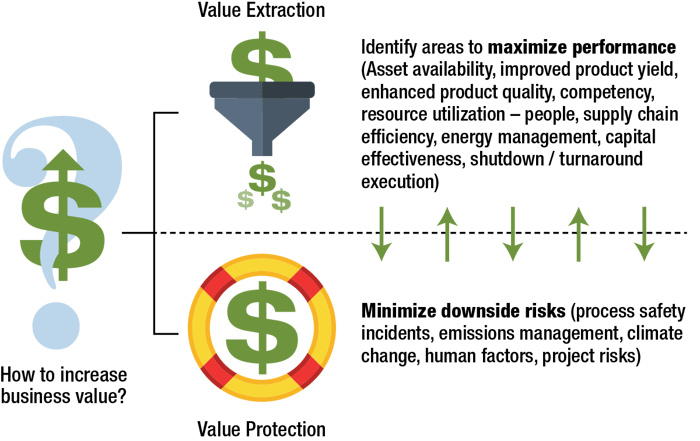

EHS is largely a value protection or zero-sum game because it is focused on minimizing and mitigating incidents as required by compliance (see Figure 1). However, operations are where the profit is made – driven mainly by value extraction activities to maximize production. Since compliance constrains operations, it is necessary for both areas to work as an integrated whole to fully capture value from the plant.

In large part, the ability to improve Production Loss Analysis (PLA) depends on how we deal with defects. Defects can be caused by equipment failures and by human error. PLA relies on understanding the true capacity to produce, recognizing opportunities to grow capacity, and proactively seeking to reduce losses. To reduce production losses over the long term, companies need to move from reactive work to planned work and improved organizational discipline.

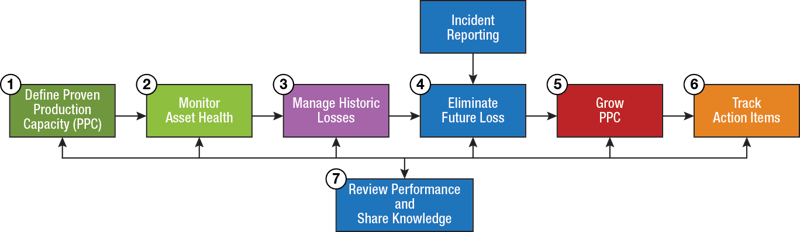

An important first step is to define the nominal production capacity as a reference for loss recording. Many discussions have been centered on the definition of ‘nominal’ in the operations context, be it name plate design capacity, upgraded capacity, theoretical maximum capacity, or something else. At OS we suggest and use the Proven Production Capacity (PPC) as the demonstrated maximum.

Asset Health monitoring (AHM) is an OESuite® module to monitor asset performance in real time and record any deviations from actual production. It also contains the ability to build predictive AI models based on signal correlation and pattern recognition to predict future losses. These current and potential future losses are inputs in our failure elimination process.

The OESuite® Failure Elimination Feature enables organizations to compare the effectiveness of their asset strategies to actual performance. Production loss events, equipment failures, process interruptions, and safety incidents are collected, analyzed, and subjected to further root cause examination.

Production loss data is applied to prioritize events and focus on the bad actor equipment. Within OESuite®, users can perform Pareto analysis and calculate Overall Equipment Effectiveness (OEE). Recommendations based on identified root causes are tracked to completion within the OESuite® platform. This systematic debottlenecking process has a positive impact on the PPC. Eventually the aim is to grow the PPC and exploit the hidden factory in your production facilities.

Integrity Operating Windows, captured in the AHM module, coupled with safe operating limits, are key to empowering field personnel with potential deviations from the expected norms that can lead to a loss of containment or potential downtime due to equipment failures.

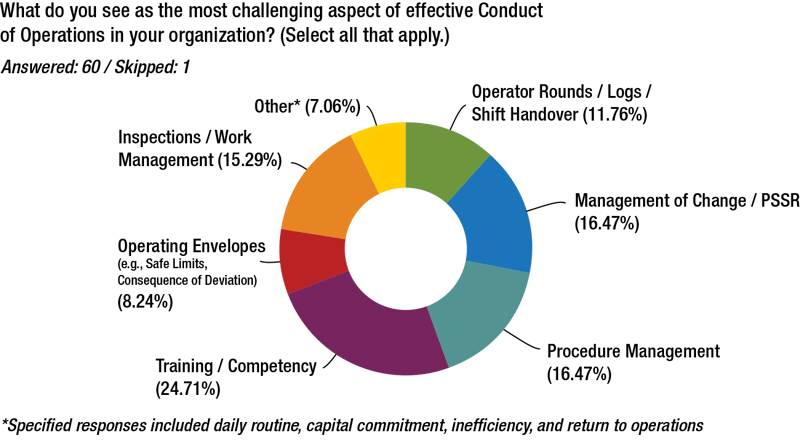

Without a mobile operations solution to help gather, analyze, and disseminate information at the point of work, companies often end up back to a spreadsheet focused on tracking lagging indicators. Our market research shows companies are largely under-automated in mobility around Conduct of Operations.

Preparing for and successfully managing through the velocity of change is key to maximizing profitability. Holistically addressing ELP requires an end-to-end solution like OESuite® that has both the incident reporting and the production loss analysis capability.

Is your organization ready to improve its ELP results? Schedule a consultation.

Topics of Interest

- Asset Strategy / Asset Performance Management (9)

- Compliance Management (4)

- Conduct of Operations (11)

- Cultural Safety (4)

- EHS / Sustainability (2)

- Enterprise Loss Prevention (8)

- Management of Change (8)

- Mechanical Integrity (3)

- Mobile Applications (5)

- Operational Excellence (11)

- Operational Readiness (7)

- Operational Risk Management (14)

- Organizational Performance (7)

- Press Releases (7)

- Process Safety / RMP (22)

- Production / Value (3)

- Workforce Competency / Connected Workforce (11)