Why Effective Equipment Identification Matters and How to Do It

March 21, 2019

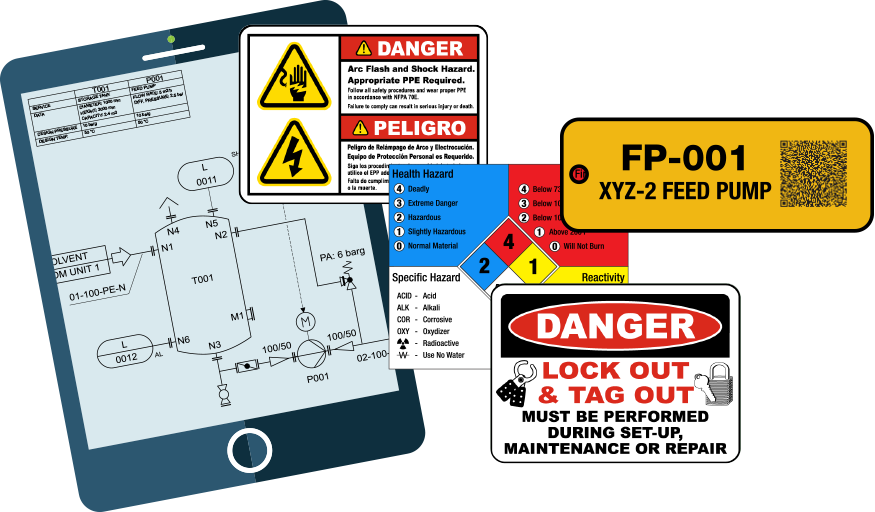

Since vision tends to dominate the senses, one of the most effective ways to reduce human error and improve human performance is to maximize visibility of equipment and its conditions. While there are many methods for improving visibility included in any good Conduct of Operations Management System, an effective equipment identification system is a critical element. Equipment needs to be identified to:

- Aid the operators and mechanics in identifying the correct equipment to reduce the possibility of operating or working on the wrong equipment

- Provide warning of specific hazards

- Identify equipment critical to emergency response

- Enhance training effectiveness

- Minimize risks and workplace hazards

Okay, so what should your Equipment Identification System look like?

It should include general requirements for equipment labelling information and maintenance. For example:

Label Information

- Equipment labelling shall use standard nomenclature for names and numbers on equipment

- Equipment labelling shall use standard prefixes to designate type of equipment

- Equipment labelling shall use standard suffixes to designate the service

- The label should provide a concise and meaningful description of the function and a unique alphanumeric code identifying the system and component

- Names and alphanumeric codes should be consistent with those used in piping and instrument diagrams, engineering drawings, procedures, shift logs, operator round check-sheets and control panels attached to equipment being controlled

- Label size needs to be large enough for viewers to see and understand at a safe distance

- When text is used in the labels the words should be spelled out. Use abbreviations when they are clear and easy to recognize, and when it is impractical to include the entire word or phrase

Label Maintenance

- Label materials shall be suitable for environmental conditions

- Procedures shall exist to ensure damaged, missing, or incorrect labels are replaced

- Operator Rounds check-sheets will include equipment label checks

- Audits, condition-based observations, and area tours will include reviewing equipment labels

- Safety critical equipment labels will be audited as part of the emergency response and planning procedures and drills

What are the specific requirements for equipment identification of the following equipment categories?

Piping Identification – consistent with ANSI/ASME 13.1

- Label information

- Label size

- Label placement

- Color coding to identify contents

- Flow direction

Vessel Identification

- Label information

- Label size

- Label placement

Rotating Equipment Identification

- Label information

- Label size

- Label placement

- Duration of rotation

Other Equipment Identification

- Instrumentation components identification using tags consistent with ANSI/ISA S5.1

- Electrical equipment identification consistent with the National Electrical Code (NEC)

- Lifting devices identification and load rating

If not – we can help!

If you're interested in developing or improving your Equipment Identification System, or any other element of Conduct of Operations, Operational Sustainability® has developed Standards, Procedures, and Field Guides (pocket procedures) for Conduct of Operations elements including Equipment Identification and can provide support and consultation including assessments and/or implementation.

Topics of Interest

- Asset Strategy / Asset Performance Management (9)

- Compliance Management (4)

- Conduct of Operations (11)

- Cultural Safety (4)

- EHS / Sustainability (2)

- Enterprise Loss Prevention (8)

- Management of Change (8)

- Mechanical Integrity (3)

- Mobile Applications (5)

- Operational Excellence (11)

- Operational Readiness (7)

- Operational Risk Management (14)

- Organizational Performance (7)

- Press Releases (7)

- Process Safety / RMP (22)

- Production / Value (3)

- Workforce Competency / Connected Workforce (11)