Operational Performance Management

July 15, 2020

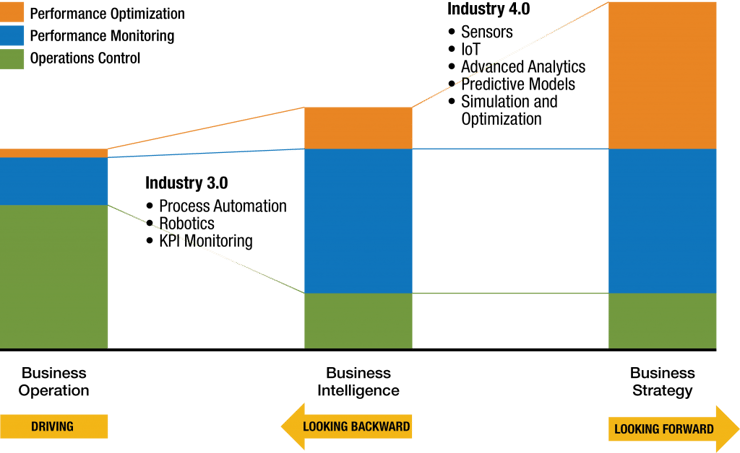

In operating facilities, millions of data points and billions of records are created daily. In fact, one terabyte of production data is being generated every hour across industries, but less than one percent is analyzed and acted on, according to BISTel. With the advent of the fourth industrial revolution, companies have access to algorithms along with Artificial Intelligence (AI), and they are quickly moving to the cloud to leverage appliances and access industry-specific algorithms. Data is moving away from data historians and toward an increased leverage of sensors that let us look forward, not backward.

As companies seek to break down departmental barriers and pursue Operational Excellence, Operational Performance Management (OPM) is an emerging framework that leverages prescriptive analytics and AI to develop new insights into threats and performance of assets (e.g. asset health and human assets). Companies need to rethink how they gather and analyze data to get meaningful information along with actionable outcomes that drive performance improvement.

OPM

OPM unifies existing organization and facility management strategies to support Organizational Resiliency. OPM helps companies to make timely, informed decisions to avoid unplanned equipment outages, while reducing inspection, maintenance and lifetime asset costs.

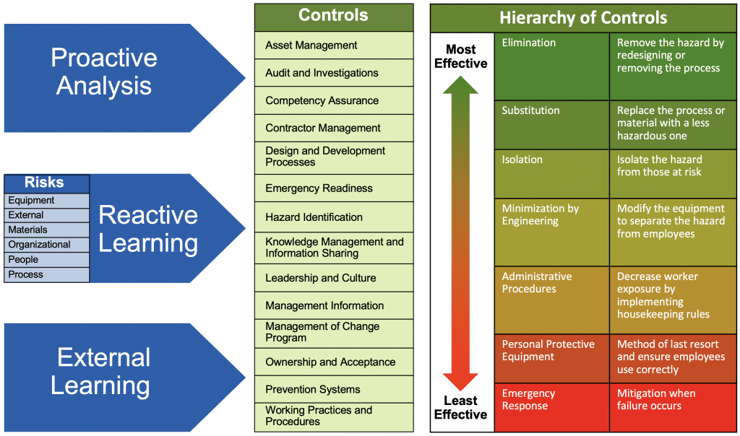

Without a strategy, the potential for unintended consequences exists. You can never eliminate all of the risk inherent in operations. We have to live with some risk. The question is, what level of risk is acceptable? As we progress toward the risk matrix in this discussion, it is important to remember there are many risks that will never be eliminated from the matrix, but they can be mitigated to acceptable levels and then monitored to assure that risk doesn’t increase over time.

A connected workforce may also use other devices complementing the basic handheld device such as integrated smartwatches or fitness trackers, body cameras, wearable RFID badges and built-for-purpose smart clothing and protective gear. One constraint that needs to be addressed in the hydrocarbon market is the need for intrinsically safe devices, which may limit which hardware can be used to avoid potential ignition hazards in a chemical plant, refinery or gas plant.

OPM also moves organizations away from after-the-fact reporting to threat detection. Having the right data at the right time is key to preventing failures and incidents, which ultimately decreases risk and waste while improving profitability. Context and analysis allow you to do the right thing for your facilities, employees, and customers.

OPM also provides a continuous improvement loop so that failures (e.g., equipment, human error) are identified to ensure management strategies are updated and patterns are identified to mitigate potential emerging threats to keep them from manifesting as Enterprise Losses.

Conclusion

With OPM, you can be confident in your operating plan, without putting your privilege to operate at stake. As losses occur, you can put bad actors on watch lists and analyze patterns to ensure strategic organizational objectives continue to be met. OPM provides a critical element will be understanding the strategic value of managing incidents and tying that understanding to financial outcomes (i.e. extended equipment outages due to supply chain issues or lost production).

Compliance constrains operations. Operations is the engine driving financial performance and enabling business strategy. If your facility employs a comprehensive management strategy that supports successful execution, safety and compliance are already integrated into each step of the operation.

By focusing on Operations first, compliance becomes a byproduct of an effective strategy. After all, OPM leads to consistent execution resulting in safe and compliant operations. Early prediction is the key to continuous improvement and OPM ensures your organization is aligned in that mission, supporting Operational Resiliency and Operational Excellence.

If you’re interested in finding out more, please visit our Intelligent Operations page.

Topics of Interest

- Asset Strategy / Asset Performance Management (9)

- Compliance Management (5)

- Conduct of Operations (11)

- Cultural Safety (4)

- EHS / Sustainability (3)

- Enterprise Loss Prevention (8)

- Management of Change (8)

- Mechanical Integrity (3)

- Mobile Applications (5)

- Operational Excellence (11)

- Operational Readiness (7)

- Operational Risk Management (15)

- Organizational Performance (7)

- Press Releases (7)

- Process Safety / RMP (23)

- Production / Value (3)

- Workforce Competency / Connected Workforce (11)